Garment factory plan detail Cadbull

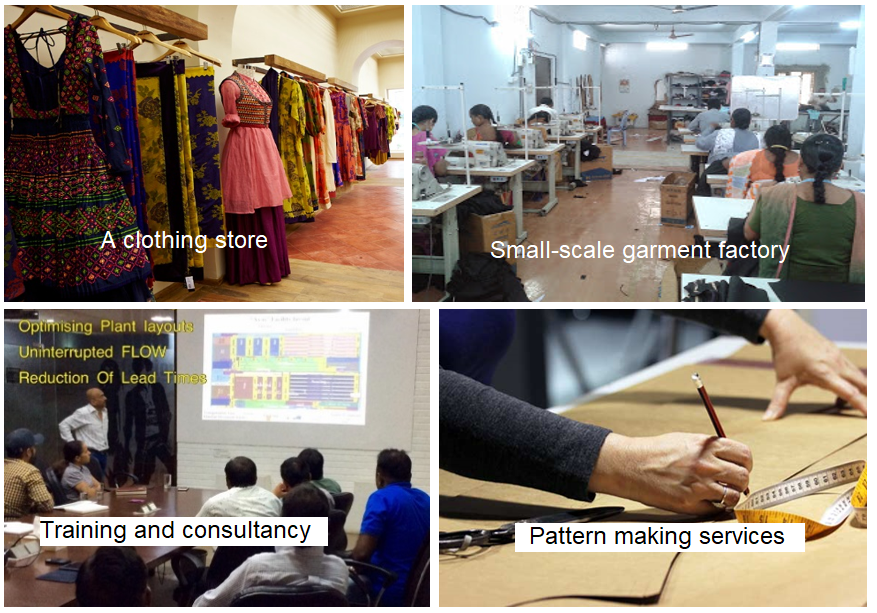

Mini Garments Factory | Practical Video | How to make garments factoryMaking a small garment factory is a dream of many people but due to lack of complete in.

Small Garment Factory Gold Garment

1. Do research on readymade garment business The readymade garment industry is huge. The garment manufacturing process is a complex one as well. At the initial stage, you should explore the garment business in a wider prospect. Study the whole apparel supply chain. When you will be doing research work find the answer to these questions.

Factory New.jpg (760×602) Factory architecture, Floor plans, Building layout

Basic requirements to set up a garment factory: Decide the product. Decide your budget. Make a list of machinery. (As per product and budget) Make a list of potential customers and start contacting them. An expert will guide you. Target market to sell. (Decide weather you wanna sell directly or job working) Target production as per sell and budget.

Plant organization pt. 2 FashionIncubator

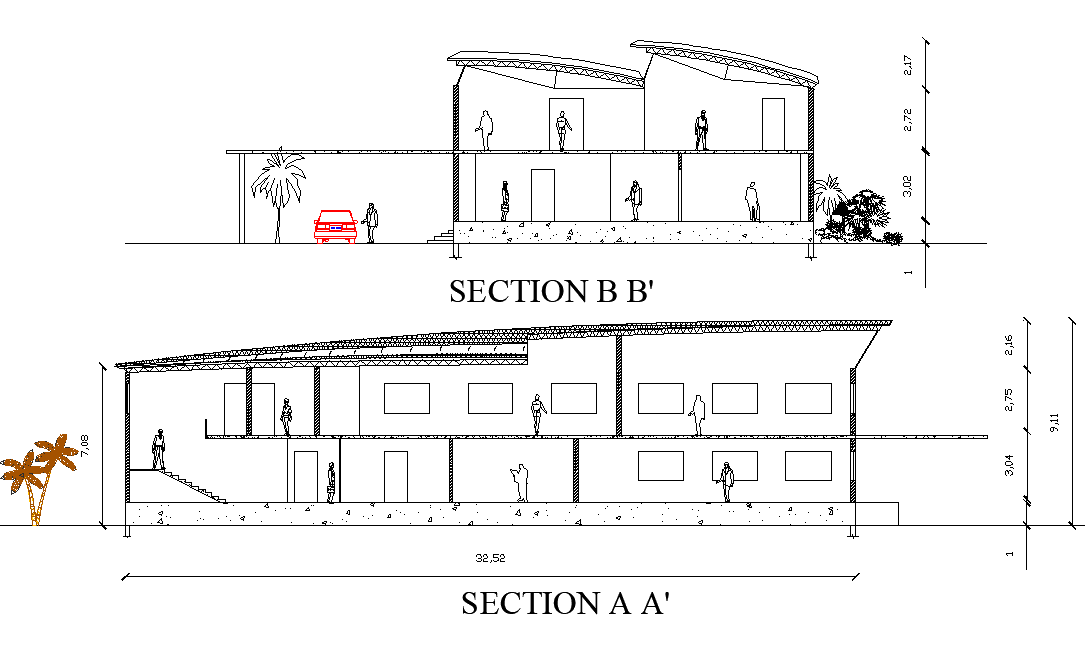

Factors to be considered for designing an effective layout include number of workers both male and female, number of machines (size, weight by models), entrance, exit and passages (size, width, position, number of each of them) for production as well as administrative wing, change room, lunch room, lavatories, medical emergency room and provisio.

Factory Design Utilities Software 2022 Download & Pricing Autodesk

Step#3 Create Your Designs. Once you've found a small scale garment factory, it's time to start creating your designs. If you're not a designer yourself, you'll need to hire one. Once you have your designs ready, you can send them to the factory for sample making.

KGI Garment Factory Shilpa Architects

Principles of Plant Layout in Garment Industry: The following principles have to be followed to have an ideal plant layout for garment industry. The understanding of these principles would help in learning the aspects that are influencing the plant layout in garment industry. 1. Principle of Minimum Travel:

IE in Apparel Manufacturing8 Layout Planning Apparel Resources

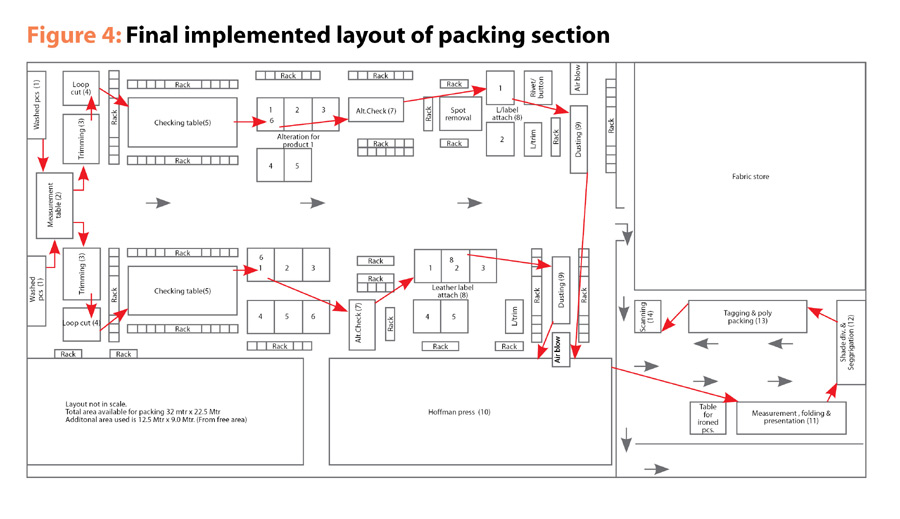

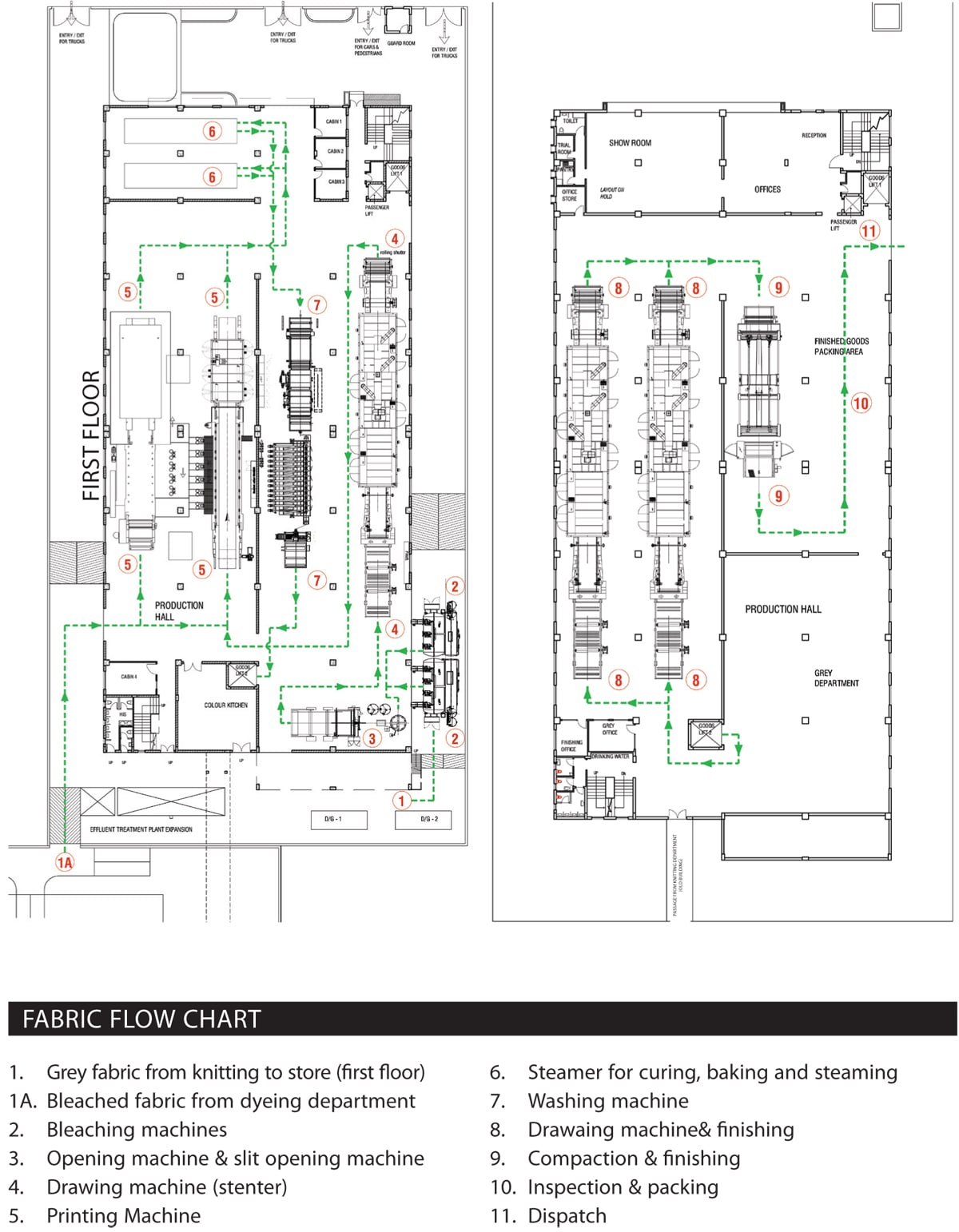

The material flow analysis was done by considering load matrix and cost matrix. After analysis of existing plant layout, three alternative layouts are developed by using SLP technique. The efficient plant layout developed has resulted in 55.25% savings in material handling distance and about 16.66% increase in productivity.

What's inside garment factory? Answer in fashionpedia book! Tekstil

Introduction The layout of a garment factory is associated with a good workflow which includes things such as receiving materials and sending the finished goods out of the garment factories. Therefore the type of apparel plant you develop directly must be optimized according to time and flexibility.

Garment Factory In Sittway Provides More Than 100 Jobs Global New Light Of Myanmar

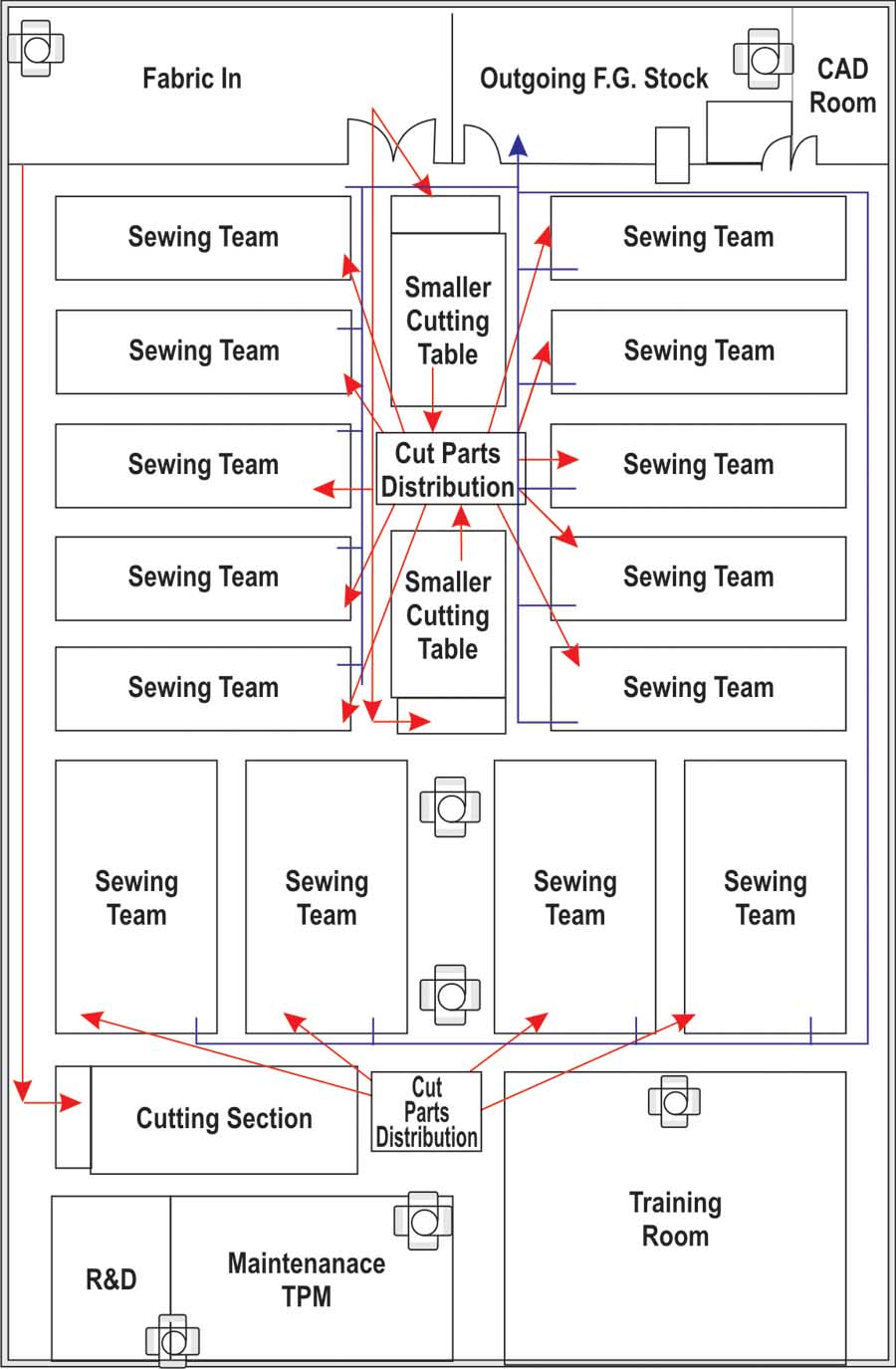

The physical layout of the factory was already well underway when the management team realized that to be truly lean, reduce transportation and WIP and have a visual control of production; the central cutting room idea would have to be replaced by placing spreading and cutting tables with the sewing teams.

Garment Factory Design on Behance

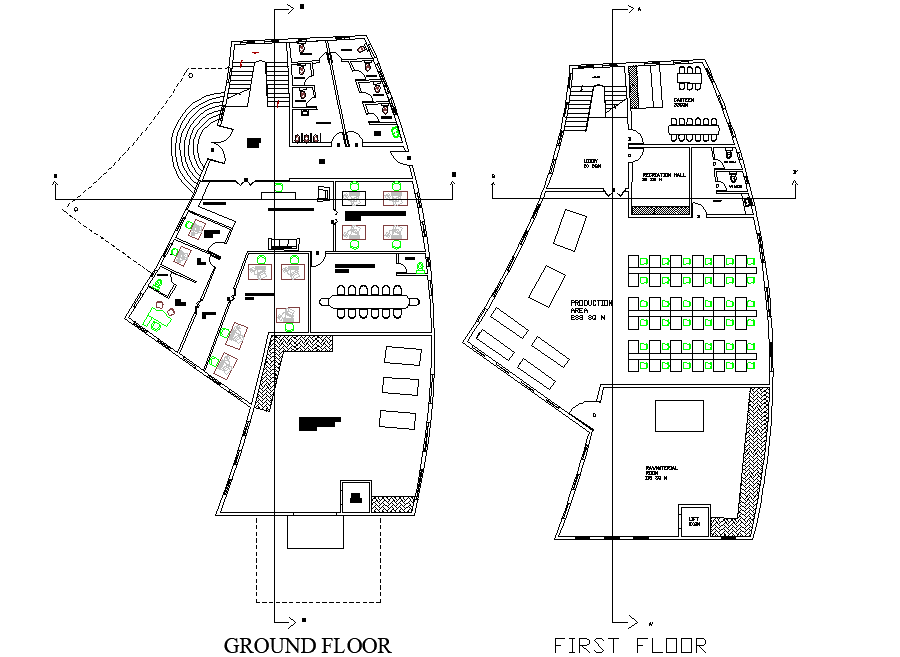

Home All Category Industrial Factories Garment Factory Design DWG Detail Download Autocad Design By amit.chuchra3982_7171 Autocad and Working drawing of a Garment factory in size (60x30 mt.), has been designed on a G+2 floor with one basement.

The Best Factory Floor Plan Design Layout And Review Floor plan design, Plan design, Layout design

ative layo. A n Optimal Layout Design in an Apparel Industry by Appropriate Line Balancing: A Case Study. G lobal Journal of Researches in Engineering. G Volume XIV Issue V Version I. Year 2014. T.

Section Garment factory plan detail Cadbull

Created by VideoShow:http://videoshowapp.com/freeThis is the 1st Part of full STEPS..In this video, we have explained, how to set up a small Garments Factory.

Cheap Labour Wins with Shift from China to India

Types of Layouts Basic Layout Flow forward layout: Materials are collected from behind and to the left of each operator, who then deposits the processed good in front of the next operator on the table. This strategy is best for large production quantities with few pieces of equipment used by each operator. Figure 1: FLOW FORWARD LAYOUT

Modular Factory Layout Case Studies Apparel Resources

A well-planned layout is crucial for maximizing production and optimizing space in a sewing or garment factory. With the right floor plan, you can make the most of your resources, reduce waste, and improve your bottom line. In this guide, we'll discuss the importance of a well-planned layout for a small garment factory. We'll explore […]

An Architect’s Advice for Building Efficient Factories Apparel Resources

No Minimums. Our *no-minimum production facility is equipped to produce almost any design or sewn product. This is a test factory. We offer no minimums so you can start off with a small test run to test the sizing or test the market before investing in larger quantities. In manufacturing, small batches = higher price per unit.

Garment Factory Illustrations, RoyaltyFree Vector Graphics & Clip Art iStock

But sometimes small changes work wonders. Suresh Durejain this article, outlines the basic considerations when conceptualizing and designing a factory layout. The plant layout is the spatial arrangement and configuration of departments, workstations, machinery and equipment used in the conversion process. The layout of a garment production.